Excavator Grabs & Grapples

September 11, 2025

Why Hiring Construction Equipment Is the Smartest Choice for Your Next Project

January 21, 2026Sheet Piling: A Complete Guide

When excavation depth increases or groundwater shows up uninvited, sheet piling steps in to keep everything steady and dry. It’s the method behind a lot of the clean, safe, and workable sites you pass without thinking, retaining soil, holding back water, and making vertical cuts possible where the ground would otherwise cave in.

You’ll see it on everything from temporary trench work to permanent retaining structures. The materials vary, the installation methods depend on the ground and the stakes, quite literally, run deep. Whether you’re pricing a job, reviewing a method statement, or just trying to avoid rework, knowing where sheet piling fits (and where it doesn’t) is worth your time.

What Are Sheet Piles?

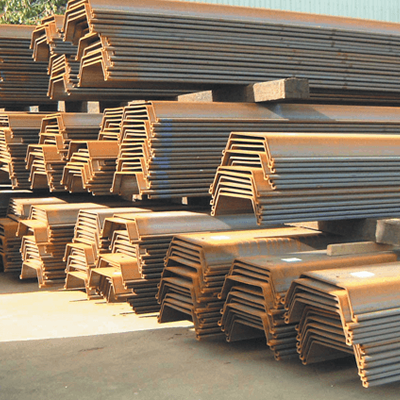

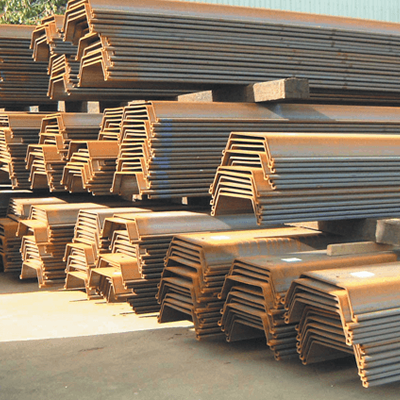

Sheet piles are long, interlocking sections (most commonly steel) driven into the ground to form a continuous barrier. Their job is to retain soil or control water, often both at once. The interlock gives the wall its integrity, and when installed correctly, the piles act as a single, stable structure.

Steel is the standard for most New Zealand sites. It’s strong, reusable, and suited to everything from short-term trench support to permanent retaining walls. Its ability to handle pressure, both structural and hydraulic, makes it reliable across a wide range of jobs. Other materials, like vinyl, composite, concrete, or timber, exist, but they tend to be used in more specific cases. Timber, for instance, works fine for shallow, low-stress applications. Vinyl and composites are corrosion-resistant but don’t offer the same load capacity. Concrete piles are heavy and durable, but need a bigger setup to install.

In practice, steel covers the majority of use cases because it balances strength, speed of installation, and availability. It’s also easy to pull and reuse, which keeps things efficient on temporary worksites.

Applications of Sheet Piles

The most common reason to use sheet piles is simple: you need to dig deep, and the ground won’t hold itself up. Whether it’s to keep a trench open or to stop water pouring in, sheet piling offers a clean, controlled way to work below surface level.

Temporary sheet piling is used across all sorts of civil works: pipe runs, manholes, lift pits, and any site where unsupported excavation would be unsafe. It’s also standard on cofferdams, especially for water-based work where you need a dry space to pour concrete or install footings.

On the permanent side, sheet piles show up in retaining walls, sea walls, flood protection systems, and basement structures. You’ll find them in infrastructure projects where the design needs to resist earth pressure or groundwater over the long term. Transport projects and utility upgrades often rely on them, particularly when space is tight and open-cut excavation isn’t an option.

The decision between temporary and permanent piling usually comes down to cost, access, and whether the piles can be extracted cleanly once the job’s done. Either way, the technique gives crews safe working conditions and keeps surrounding structures or services from shifting while the ground is open.

Benefits of Sheet Piling

Sheet piling is valued because it works simply and reliably.

Key benefits include:

- Fast installation: With the right method and gear, sheet piles can be driven quickly, even in poor ground or wet conditions.

- Water control: Properly interlocked piles form a reliable barrier against groundwater and tidal flow, making them ideal for marine, coastal, or below-water-table sites.

- Reusability: For temporary work, piles can be extracted and reused elsewhere, reducing both material cost and waste.

- Consistent performance: Steel sheet piles deliver reliable structural support across a range of soil types and loading conditions.

- Low disruption: Installation can be done in built-up areas with minimal noise or vibration, especially when using hydraulic pressing or other low-impact methods.

- Adaptability: They work with a range of digger and excavator attachments, integrate into different project designs, and suit everything from infrastructure builds to emergency stabilisation jobs.

Together, these advantages make sheet piling a practical, cost-effective solution across a wide range of ground engineering challenges.

Sheet Pile Installation Methods

The way sheet piles go into the ground depends on the site, the soil, and what’s nearby. Each method has its place, and choosing the wrong one can cause delays, damage, or unnecessary disruption. Here’s a breakdown of the most common approaches used across New Zealand job sites.

Vibratory Hammers

Vibratory hammers use high-frequency vibrations to reduce soil resistance and drive piles into place quickly. They’re efficient, relatively quiet, and suitable for most soil types. This method works well on urban sites or time-sensitive projects where productivity matters but excessive noise isn’t acceptable.

Impact Driving

When the ground is dense, compacted, or full of obstructions, impact driving is often the only option. It uses a heavy drop hammer or diesel hammer to deliver direct force. It’s louder and more disruptive but highly effective in tough ground where vibration alone won’t cut it.

Hydraulic Pressing

Hydraulic pressing offers a low-noise, low-vibration alternative, especially suited to residential or built-up areas. It uses a silent pusher to install piles by pressing them into the soil without impact or vibration. Slower than other methods, but it keeps the peace in sensitive environments.

Jetting and Trenching

Jetting and trenching use water or air to loosen the soil ahead of pile insertion. It’s not commonly used, but in soft, sandy, or marine conditions, it can help reduce friction. The method is limited and typically used alongside other installation techniques.

Considerations and Limitations

Sheet piling works well in a range of conditions, but it’s not without challenges. Understanding the limitations early can prevent issues that affect time, cost, or safety.

Noise and vibration are key concerns, especially on sites near homes, schools, or businesses. Methods like impact driving may be off the table in built-up areas due to local restrictions or environmental sensitivity. Hydraulic pressing offers a quieter alternative but takes longer and may not suit all ground types.

Skill also matters. Poor installation, whether due to the wrong method, incorrect alignment, or mismatched gear, can cause long-term structural issues. Sheet piling isn’t a job for guesswork. Planning needs to factor in ground reports, access, nearby structures, and the right equipment. Experienced operators with the correct tools are essential.

Sheet Pile Selection and Hire Guidance

Getting the right sheet pile comes down to understanding your site and your load requirements. It’s not just about length; profile shape, thickness, and material all play a role in performance.

Steel piles are the standard choice for most commercial and infrastructure work. They handle the heaviest loads and allow for deeper excavation. Timber might work for shallow trenching or short-term work, but it’s not a long-term solution. Vinyl or composite piles suit corrosive environments but offer lower structural capacity.

Choosing the right profile affects how well piles interlock and how much force they can resist. Thicker piles provide more durability but require heavier gear to install. It’s also essential to factor in groundwater, because when water pressure is an issue, watertightness becomes just as important as structural capacity.

Need Sheet Piles on Your Next Job?

Whether it’s a quick trench support or a permanent retaining structure, sheet piling does what it’s meant to: keeps the ground where it should be and the job moving safely. But getting it right means having the right gear, the right method, and a supplier who actually knows how this stuff works on site.

At Pilehire, we supply sheet piles and all the attachments you’ll need to install them properly. Every piece of equipment is maintained, fit-checked, and backed by advice from people who’ve seen enough jobs to know what works where.

If you’ve got a piling job coming up, talk to us early. We’ll help you sort the right gear, make sure it fits, and get it delivered when you need it.

Browse our piling gear here or give the team a ring to get started.